Egypt Plastic Injection Molding: Emerging Technologies and Key Trends

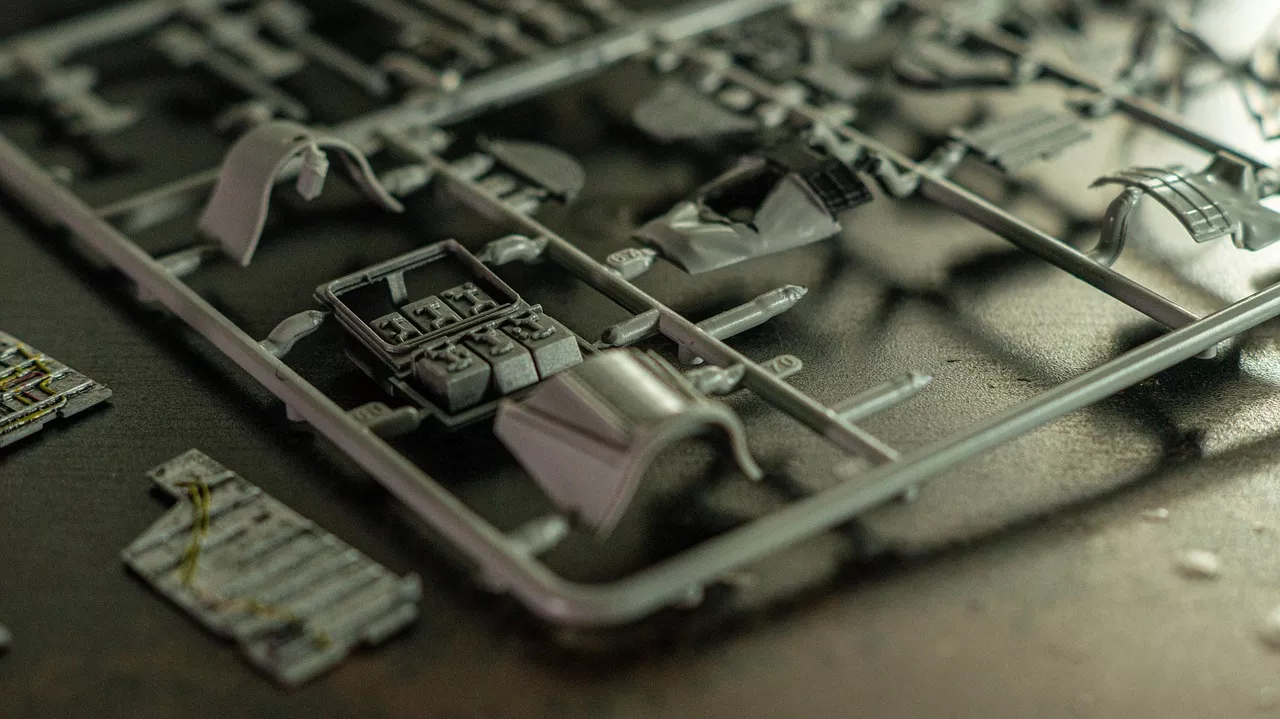

Plastic injection molding has developed into the core manufacturing process for numerous sectors, including automotive, construction, healthcare, pharmaceuticals, medical devices, military, and transportation

Plastic injection molding has developed into the core manufacturing process for numerous sectors, including automotive, construction, healthcare, pharmaceuticals, medical devices, military, and transportation. Its dominance stems from the technique’s ability to generate a diverse array of components at comparatively lower cost and within reduced lead times.

The process is centred on the heating and homogenisation of polymer pellets, enabling the subsequent injection of the molten mass into precision-engineered cavities. As the polymer cools, the part acquires the intended geometry, surface finish, and mechanical integrity, resulting in components that meet stringent tolerances and performance criteria.

Analysts at GMI Research estimates, the Egypt Plastics Market is estimated to grow at a promising CAGR of 3.3% during the forecast period 2025-2032

A Historical Perspective on Technological Advancements

Originating in the 19th century, the injection molding process has experienced a progressive series of innovations that have progressively influenced production efficiency, scalability, and flexibility. The first recorded patent, granted in the 1870s to John and Isaiah Wesley Hyatt, described a rudimentary machine that employed a hand-operated screw to force molten celluloid into flat dies. Despite its constraints in detail and production rate, the invention provided a conceptual framework for subsequent mechanical, thermal, and control enhancements that have culminated in semiconductor-enabled, multi-material molding systems summarised in succeeding sections.

The ensuing decades witnessed a dramatic expansion in component fabrication, buoyed in part by the advent of Computer Numerical Control (CNC) machining in the 1970s, which streamlined the design and production of reusable molds. Concurrently, advancements in automation and a decline in manual labor ensured that injection-molding technology became the predominant process embraced by the manufacturing sector.

Emerging Innovations and Directions in Plastic Injection Molding

Although plastic injection molding remains a cornerstone of contemporary production, the process continues to adapt in response to shifting market criteria. Within this ongoing evolution, a number of distinctive trends are charting the trajectory of the discipline.

Expanding Spectrum of Polymers for Injection Molding

Possibly the most consequential alteration to the discipline has been the emergence of an extensive portfolio of novel plastic formulations. Facilities are progressively empowered to select thermoplastics that exhibit tailored mechanical behaviour, distinguished by matrices of composition, chromatic properties, optoelectronic clarity, energy-dissipation, and compliance characteristics.

The widening phase space of injectable compounds has rendered plastic molding relevant to previously incommensurable sectors. In the health-care domain, for instance, dentistry mandates devices that necessitate stringent dimensional fidelity and surface finish. Accordingly, the availability of flexible thermoplastics and clinically stable, thermally long-lasting resins anticipates not only sustenance but, more crucially, acceleration of ongoing maturation across the workspace.

Automation in the Plastic Injection Molding Process

In recent years, the plastic injection molding sector has undergone a transformative shift through the incorporation of sophisticated automation technologies, resulting in marked gains in both throughput and dimensional fidelity. Modern high-tonnage injection presses now routinely employ multi-axis robotic arms, automated material handling gantries, and closed-loop feedback control systems, significantly reducing the level of manual intervention that was once standard.

When coupled with artificial intelligence algorithms that fine-tune process parameters in real time, these systems achieve accelerated cycle times and elevated output volumes, both essential attributes for supply chains dominated by aggressive time-to-market metrics. The inherent flexibility of the integrated architecture is further enhanced by continuous process surveillance and prescriptive maintenance protocols, which not only warn operators of impending component failure but also enable self-optimizing response actions.

Industry 4.0 Production Systems

The paradigm widely termed "Industry 4.0" embodies the comprehensive digitisation of manufacturing through seamless connectivity of machines, systems, and personnel via the Internet of Things (IoT) and intelligent robotics. As a consequence, a growing number of tier-one injection molding enterprises are migrating to multi-layered, cloud-centric production ecosystems that employ real-time process analytics, cloud-based predictive maintenance clusters, and advanced data-mined, linked metrics to direct every phase of the manufacturing life cycle. Downtime, therefore, is not merely minimised in the classic sense; rather, the production floor acquires the capability to reconfigure itself to sudden demand fluctuations, assuring agility within an ever-accelerating and volatile marketplace.

Sep 25, 2025